All our machines are available with practical accessories. There are easy-to-use gas mixers and analysers for modified atmosphere packaging.

In modified atmosphere packaging (MAP), the food can be protected against the adverse effects of oxygen using a modified atmosphere. In modified atmosphere packaging, air containing oxygen is replaced with other gases, usually mixtures of nitrogen and carbon dioxide.

MAP, Modified Atmosphere Packaging

Longer shelf life for food products

Preserving the freshness of perishable products is a very important step in the food industry packaging process. The modified atmosphere provides food with a longer shelf life and a better and more fresh taste, colour and shape. The modified atmosphere of the food package prevents the growth of microbiological organisms and biochemical reactions and the rotting of products resulting from this. The use of a modified atmosphere is an essential part of careful quality assurance and a reliable and cost-effective alternative for cooling or preservatives.

Equipment and systems for mixing, measuring and analysing gases are available for all types of packaging machinery used in the food industry. Leak detectors, which ensure the tightness of the packages, are available as manual or fully automatic solutions. Vacuum packages or products without carbon dioxide may also be tested for leaks.

Questions about modified atmosphere packaging equipment?

A gas analyser monitors the correct composition of the gas mixture

A gas analyser is an integral part of a MAP process' quality control. It analyses the values of residual oxygen, carbon dioxide and nitrogen in the gas mixture. Gas analysers are extremely accurate, fast and require only a very small amount of gas. All data is logged and can be archived for quality assurance documentation.

Gas analysis may be performed as a continuous analysis during the packaging process, or separately after the packaging process, by taking a test sample. In continuous monitoring, the fixed analyser module is integrated into the gas mixing system, which continuously monitors the composition of the gas mixture. The test sample solution uses a portable gas analyser equipped with a needle to take a gas sample from the packaging.

A gas mixer produces the desired gas mixture

In most cases, gas mixers are used to produce MAP gas mixtures. They control the quality of gas in order to enable the production of food that is free of bacteria and which has a longer shelf life. At the press of a button, a variety of mixtures can quickly be produced at the packaging line, according to the requirements of the product that is about to be packaged.

Gas mixing and measurement systems are available for all packaging machines used in the food industry, be they vacuum packaging, thermoformer, flowpack or chamber machines.

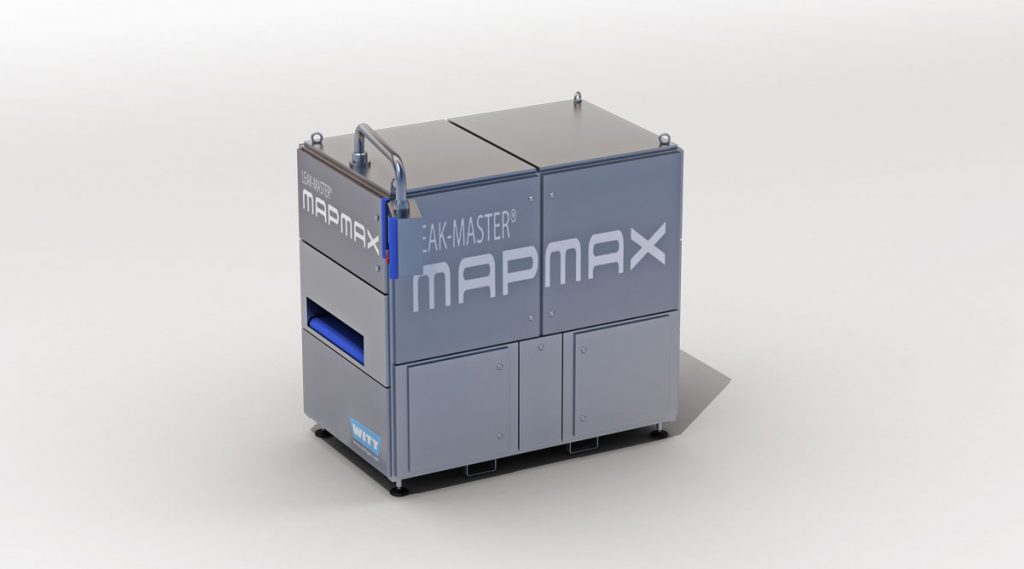

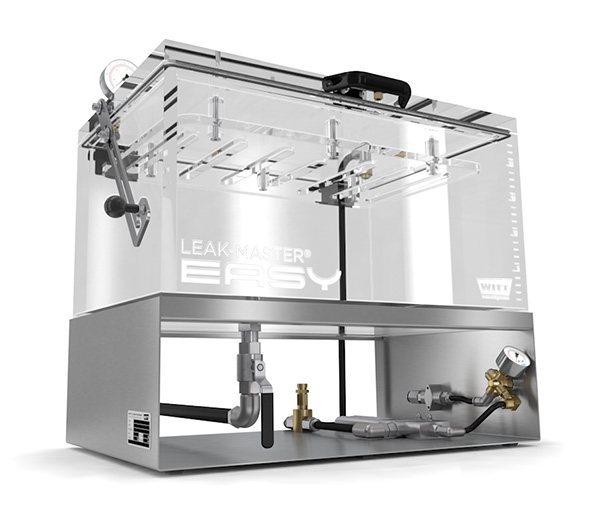

A leak detector is used to check that the sealing will hold

The modified atmosphere is only useful if it remains inside the packaging, which is why the packaging must be completely tight. Defects in the sealing process or material can easily lead to leaks, the size of which can be microscopic. Thus, detection of packaging leaks or integrity testing of package sealing is an essential part of quality assurance.

A leak detector is used for detecting leaks in all types of food packaging, be it modified atmosphere packaging or vacuum packaging. There are various devices for detecting package leaks through random tests or in-line tests – based on either CO22detection or bubble test of a water bath. Leak detectors reliably detect even the smallest of leaks. Tests can be recorded digitally and documented to prove product safety.